As a pet products factory with 14 years of experience, we are familiar with the entire process of product customization. Whether you are working with us for the first time or developing new products, we can provide you with comprehensive support during the product proofing process.

First, we can define the customized product: whether it is a pet ramp, camp bed, or soft-sided box. Then, we can confirm the target user and customer purpose of each product. Then we come to the most complex step: confirming the product specifications. This includes:

At this time, we usually send the corresponding drawing link for preliminary reference, and then use the customer demand form to record all detailed requirements.

After understanding the general needs of the customer, we will independently conduct an engineering review to determine whether molds, structural adjustments, or supply chain coordination are needed. We usually consider:

After conducting a preliminary proofing process review, we need to confirm the final proofing quotation and cycle to clarify the boundaries of responsibility. In this process, we will take into account:

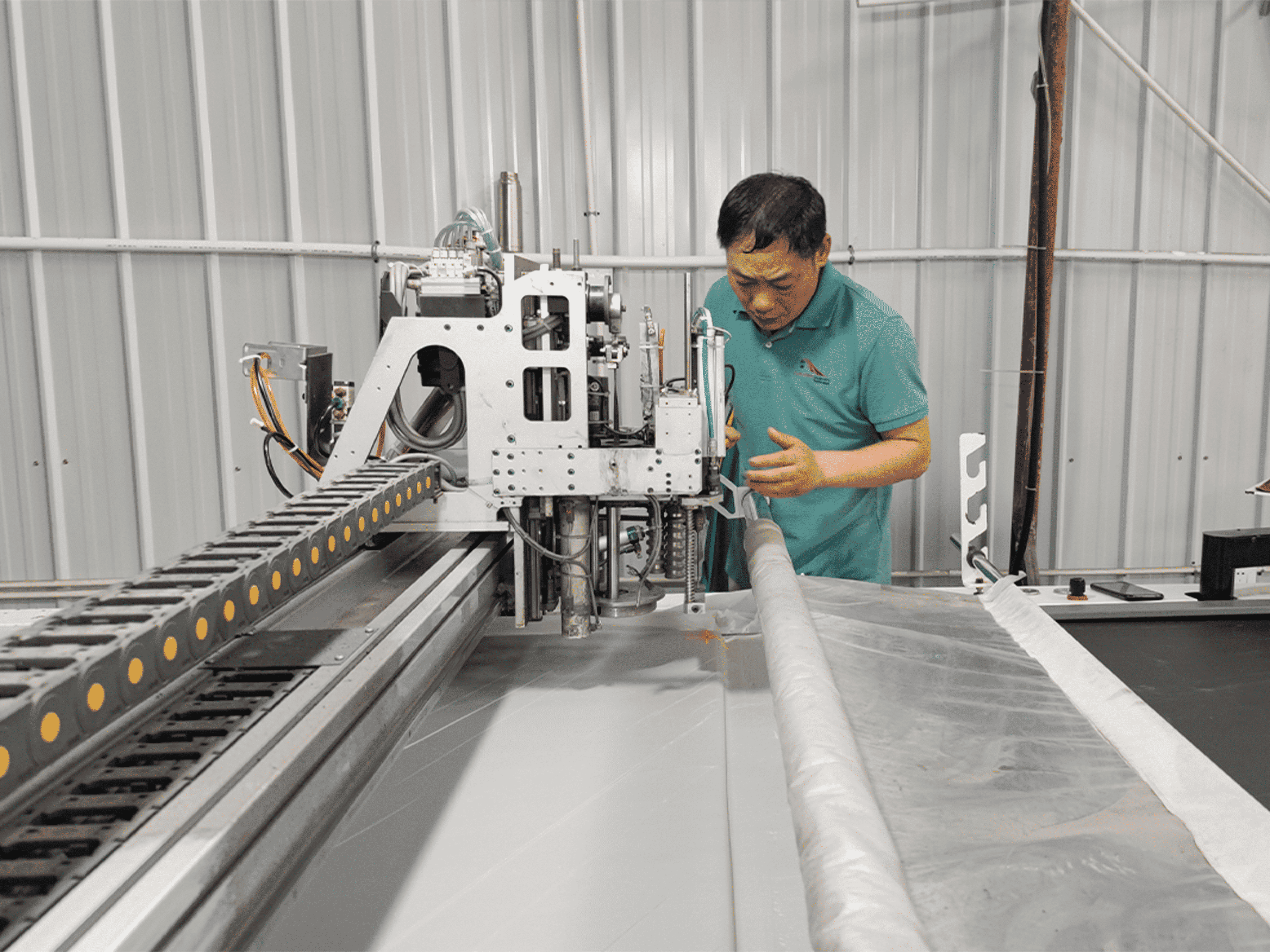

After confirming the basic data, we enter the sample production stage, which is also the process we pay the most attention to, because it determines to some extent whether our subsequent cooperation will be smooth. We will make samples that are the same as the finished product to ensure consistent quality:

After the proofing process is completed, it is time for us to send it to the customer for confirmation and feedback. The goal is to obtain modification suggestions or confirm the basis for mass production:

After both parties confirm the samples, they can be recorded and filed, providing a standard basis for subsequent orders/repurchases:

Therefore, it is very necessary to understand the product proofing process, which can help customers understand the product in a comprehensive and transparent manner and feel at ease throughout the process!